×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Drive Belts found

Nissan Maxima Fan & Alternator Belt

Part Number: 11720-JA10B$62.52 MSRP: $90.55You Save: $28.03 (31%)Ships in 1-2 Business Days

Nissan Maxima Belt-Fan

Part Number: 11720-6TA0A$56.59 MSRP: $81.97You Save: $25.38 (31%)Ships in 1-2 Business Days

Nissan Maxima Alternator Belt

Part Number: 11950-8J100$38.65 MSRP: $62.37You Save: $23.72 (39%)Ships in 1-3 Business Days

Nissan Maxima Fan & Alternator Belt

Part Number: 11720-3WS0B$56.59 MSRP: $81.97You Save: $25.38 (31%)Ships in 1-2 Business Days

Nissan Maxima Power Steering Oil Pump Belt

Part Number: 11950-31U02$41.60 MSRP: $60.25You Save: $18.65 (31%)Ships in 1-3 Business Days

Nissan Maxima Air Conditioner Compressor Belt

Part Number: 11920-2Y501$29.71 MSRP: $51.63You Save: $21.92 (43%)Ships in 1 Business Day

Nissan Maxima Power Steering Oil Pump Belt

Part Number: 11950-31U00$41.60 MSRP: $60.25You Save: $18.65 (31%)Ships in 1-3 Business Days

Nissan Maxima Air Conditioner Compressor Belt

Part Number: 11920-CK000$36.14 MSRP: $52.33You Save: $16.19 (31%)Ships in 1-3 Business Days

Nissan Maxima Compressor Belt

Part Number: 11920-31U02$27.84 MSRP: $48.38You Save: $20.54 (43%)Ships in 1 Business Day

Nissan Maxima Compressor Belt

Part Number: 11920-7Y000$32.77 MSRP: $47.45You Save: $14.68 (31%)Ships in 1-2 Business Days

Nissan Maxima Fan & Alternator Belt

Part Number: 11720-3WS0C$56.59 MSRP: $81.97You Save: $25.38 (31%)Ships in 1-3 Business Days

Nissan Maxima Power Steering Oil Pump Belt

Part Number: 11950-31U01$41.60 MSRP: $60.25You Save: $18.65 (31%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 29 Results

Nissan Maxima Drive Belt

If you need any OEM Nissan Maxima Drive Belt, feel free to choose them out of our huge selection of genuine Nissan Maxima Drive Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Drive Belt Parts Questions & Experts Answers

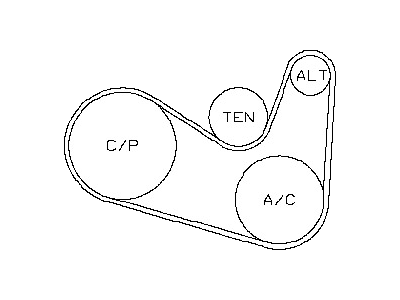

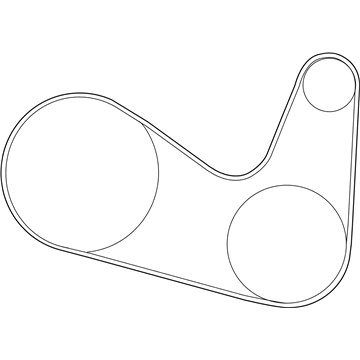

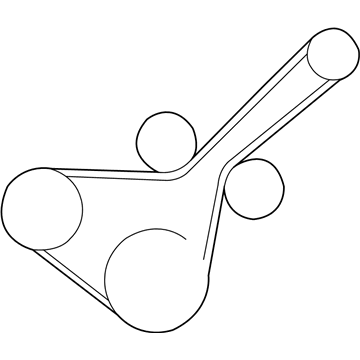

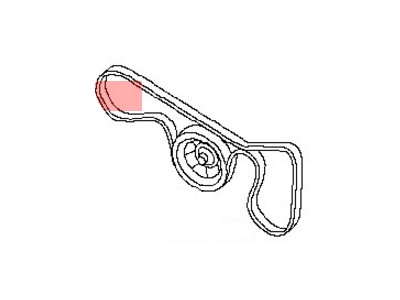

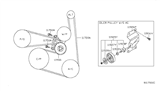

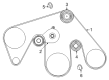

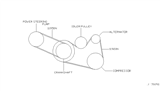

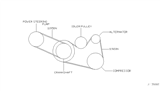

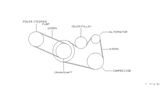

- Q: What is the importance of drivebelts in an engine and how should they be inspected and replaced on Nissan Maxima?A:Drivebelts situated at the front of the engine are essential to the engine and all related parts. It is advisable to check these belts regularly because as a result of their functioning and the composition of their material, they are subject to wearing. The early version has three belts, namely serpentine, and V belts, and those manufactured from 1995 have two serpentine belts only. The drivebelts are designed to turn the alternator, power steering pump, water pump, and A/c compressor incase of an equipped vehicle. To inspect belts, the first step is turning off the engine, opening the hood, and to evaluate the condition of the belts, one can use fingers and, if needed, a flashlight; the areas to pay attention to are cracks, separations, fraying, and glazing on the sides of the belt by twisting it. On the underside there should be ribs which should be of equal thickness. An easy way of checking the belt tension is by pressing the belt between two pulleys; where the distance is between 7-11 inches, ¼ inch should be deflected while for the 12-16 inches ¼ to ½ inc should only be deflected. Common among three-belt models is where one belt turns the water pump and power steering pump, the second turns the alternator, while the third, which is longer, turns the air conditioning compressor, all this being controlled by various idlers. Later models incorporate a single serpentine belt which is adjusted at the power steering pump and another large serpentine belt, adjusted at the upper idler. To remove the belts, you need to loosen the adjuster or component to take it off the pulleys and recall that outer belts are to be removed to expose the inner belts, nonetheless, it is recommended to replace all belts at the same time. After running the new belt over the pulleys it will require the tension to be set all over.

Related Nissan Maxima Parts

Browse by Year

2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2001 Drive Belt 2000 Drive Belt 1999 Drive Belt 1998 Drive Belt 1997 Drive Belt 1996 Drive Belt 1995 Drive Belt 1994 Drive Belt 1993 Drive Belt 1992 Drive Belt 1991 Drive Belt 1990 Drive Belt 1989 Drive Belt 1988 Drive Belt 1987 Drive Belt 1986 Drive Belt 1985 Drive Belt