×

- Live Chat

- 1-888-726-6993

My Garage

My Account

Cart

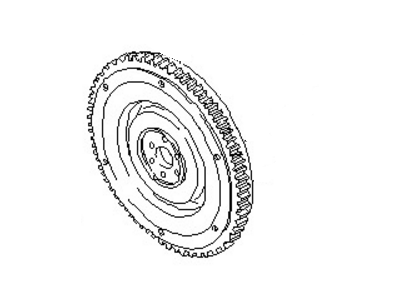

Genuine Nissan Pathfinder Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Flywheels found

Nissan Pathfinder Plate Assy-Drive & Gear

Part Number: 12331-JA10C$166.58 MSRP: $229.45You Save: $62.87 (28%)Ships in 1-2 Business DaysNissan Pathfinder FLYWHEEL Assembly

Part Number: 12310-0W001$639.93 MSRP: $881.45You Save: $241.52 (28%)Ships in 1-3 Business DaysNissan Pathfinder FLYWHEEL Assembly

Part Number: 12310-4W001$788.71 MSRP: $1095.43You Save: $306.72 (28%)Ships in 1-2 Business DaysNissan Pathfinder FLYWHEEL Assembly

Part Number: 12310-0W000$639.93 MSRP: $881.45You Save: $241.52 (28%)Nissan Pathfinder Plate Assy-Drive & Gear

Part Number: 12331-6KA0A$178.69 MSRP: $246.13You Save: $67.44 (28%)Ships in 1-3 Business Days

Nissan Pathfinder Flywheel

If you need any OEM Nissan Pathfinder Flywheel, feel free to choose them out of our huge selection of genuine Nissan Pathfinder Flywheel. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Pathfinder Flywheel Parts Questions & Experts Answers

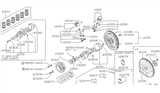

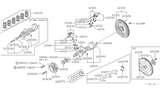

- Q: How to remove and reinstall a Nissan Pathfinder's flywheel or driveplate?A: Raise the vehicle and support it securely on jackstands, then remove the transmission. If the vehicle is equipped with a manual transmission, remove the pressure plate and clutch disc. Now is a good time to check/replace the clutch components and pilot bushing if necessary. If the vehicle is equipped with an automatic transmission, now would be a good time to check and replace the front pump seal/O-ring. Use paint or a center-punch to make alignment marks on the flywheel/driveplate and crankshaft to ensure correct alignment during reinstallation. Remove the bolts that secure the flywheel/driveplate to the crankshaft. If the crankshaft turns, hold the flywheel with a pry bar or wedge a screwdriver into the ring gear teeth to jam the flywheel. Remove the flywheel/driveplate from the crankshaft. Since the flywheel is fairly heavy, be sure to support it while removing the last bolt. Clean the flywheel to remove grease and oil. Inspect the surface for cracks, rivet grooves, burned areas and score marks. Light scoring can be removed with emery cloth. Check for cracked and broken ring gear teeth or a loose ring gear. Lay the flywheel on a flat surface and use a straightedge to check for warpage. Clean and inspect the mating surfaces of the flywheel/driveplate and the crankshaft. If the crankshaft rear seal is leaking, replace it before reinstalling the flywheel/driveplate. Position the flywheel/driveplate against the crankshaft: Be sure to align the marks made during removal. Note that some engines have an alignment dowel or staggered bolt holes to ensure correct installation. Before installing the bolts, apply thread locking compound to the threads. Wedge a screwdriver into the ring gear teeth to keep the flywheel/ driveplate from turning as you tighten the bolts to the specific torque. The remainder of installation is the reverse of the removal.

Related Nissan Pathfinder Parts

Browse by Year

2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2015 Flywheel 2014 Flywheel 2013 Flywheel 2004 Flywheel 2003 Flywheel 2002 Flywheel 2001 Flywheel 2000 Flywheel 1999 Flywheel 1998 Flywheel 1997 Flywheel 1996 Flywheel 1995 Flywheel 1994 Flywheel 1993 Flywheel 1992 Flywheel 1991 Flywheel 1990 Flywheel 1989 Flywheel 1988 Flywheel 1987 Flywheel