×

- Live Chat

- 1-888-726-6993

My Garage

My Account

Cart

Genuine Nissan Versa Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orNissan

Versa

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Drive Belts found

Nissan Versa Fan & Alternator Belt

Part Number: 11720-1KT0A$52.77 MSRP: $83.28You Save: $30.51 (37%)Ships in 1-2 Business DaysNissan Versa Fan & Alternator Belt

Part Number: 11720-EL00A$53.54 MSRP: $78.98You Save: $25.44 (33%)Ships in 1-2 Business DaysNissan Versa Fan & Alternator Belt

Part Number: 11720-ED00C$44.84 MSRP: $75.73You Save: $30.89 (41%)Ships in 1-3 Business DaysNissan Versa Alternator Belt

Part Number: 11720-BC21C$45.75 MSRP: $64.18You Save: $18.43 (29%)Ships in 1-3 Business DaysNissan Versa Serpentine Belt

Part Number: 11720-5RB0A$36.88 MSRP: $54.40You Save: $17.52 (33%)Ships in 1-3 Business Days

Nissan Versa Drive Belt

If you need any OEM Nissan Versa Drive Belt, feel free to choose them out of our huge selection of genuine Nissan Versa Drive Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Versa Drive Belt Parts Questions & Experts Answers

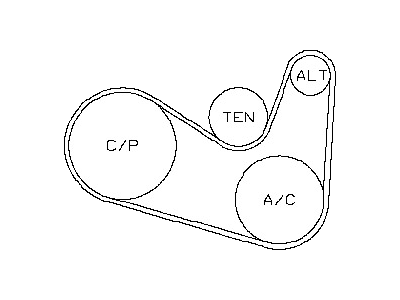

- Q: How to inspect and replace the serpentine drivebelt on Nissan Versa?A: These models incorporate a serpentine drivebelt with a tensioner; uses an automatic tensioner sees on all the 1.8L engines while a manual tensioner is used on all the 1.6 L engines. The condition and correct tension of the belt are significant in the operation of the engine because of the nature of the drivebelts, where they are made of elastic materials that become worn and stretched through use and the punishment they receive. The primary inaccuracies are observed in the manual tensioner models; therefore, they require periodic inspection and adjustment. The serpentine drivebelt is used to drive all the accessories with the help of a series of individual v-belts showing the power output. Engage the parking brake and then turn off the engine, then you locate the drivebelt by opening the hood. You need to shine a flashlight on the belt and look for indications of separation; cracks, strands, or glazing on the belt surface both when twisting it from both sides. If defects are observed on it, the belt should be changed in order to prevent further problems from cropping up. For 1.6L engines belt tension, apply extra force to it and if its deflection is okay, else replace the belt, for 1.8L engines the belt indicator shows how much stretched it is, if its beyond limits replace it. To replace the drivebelt, the negative battery cable needs to be disconnected, right front wheel's lug nuts loosened, vehicle has to be lifted securely and right inner fender splash shield has to be removed. For 1.6L models turn manual tensioner idler pulley lock nut, and the adjustment bolt of by loosening them, remove the old drivebelt, pull the idler, and pulley tighten the lock- nut temporarily while fitting the new drivebelt making sure the routing is correct, loosen the lock- nut slightly to adjust the tension and reconnect the battery. To complete the replacement of drivebelt for 1.8L models: rotate the belt tensioner clockwise to let the tension out, lock this piece, take out the previous worn drivebelt and fix the new one, and the battery connection. When replacing the tensioner, the drivebelt should be removed first, followed by the 1.6L engines which requires, the lock nut and adjustment bolt to be detached, while the 1.8L engines only necessitates the removal of the tensioner mounting bolt. Other methods include the process of installation, which is the complete reverse of the removal process, therefore tightening of all the fasteners to the required torque is done.