×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

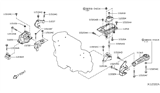

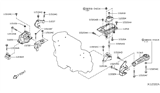

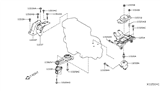

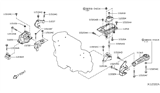

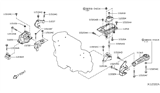

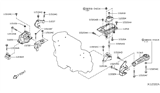

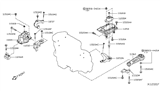

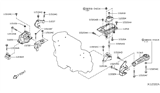

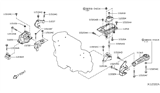

Genuine Nissan Versa Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

47 Engine Mounts found

Nissan Versa Engine Mounting Insulator, Front

Part Number: 11210-1HS0A$158.53 MSRP: $234.73You Save: $76.20 (33%)Ships in 1-3 Business Days

Nissan Versa Engine Mounting Insulator , Left

Part Number: 11220-1HA0B$98.24 MSRP: $142.27You Save: $44.03 (31%)Ships in 1-3 Business Days

Nissan Versa Engine Mounting Insulator Assembly, Front Left

Part Number: 11220-EL50A$131.34 MSRP: $190.20You Save: $58.86 (31%)Ships in 1-2 Business Days

Nissan Versa Engine Mount Bracket, Right

Part Number: 11232-EL00B$76.71 MSRP: $108.35You Save: $31.64 (30%)Ships in 1-2 Business Days

Nissan Versa Rod Assy-Torque

Part Number: 11360-1HC0D$113.29 MSRP: $160.02You Save: $46.73 (30%)Ships in 1-3 Business Days

Nissan Versa Engine Mounting Driver Side

Part Number: 11220-5RA0A$147.07 MSRP: $217.77You Save: $70.70 (33%)Ships in 1-3 Business Days

Nissan Versa Engine Mounting Insulator ,Front

Part Number: 11210-EL01B$132.97 MSRP: $192.58You Save: $59.61 (31%)Ships in 1-2 Business Days

Nissan Versa Engine Mounting Buffer Assembly, Rear

Part Number: 11360-EL00A$104.68 MSRP: $147.85You Save: $43.17 (30%)Ships in 1-2 Business Days

Nissan Versa Engine Mounting Insulator, Front

Part Number: 11210-ED800$132.97 MSRP: $192.58You Save: $59.61 (31%)

Nissan Versa Engine Mounting Bracket, Left

Part Number: 11253-EL01A$59.14 MSRP: $81.53You Save: $22.39 (28%)Ships in 1-2 Business Days

Nissan Versa Engine Mounting Bracket, Right

Part Number: 11232-EL00A$76.71 MSRP: $108.35You Save: $31.64 (30%)Ships in 1-2 Business Days

Nissan Versa Engine Mounting Support, Left

Part Number: 11254-CH000$154.31 MSRP: $217.95You Save: $63.64 (30%)Ships in 1-3 Business DaysNissan Versa Engine Torque Strut

Part Number: 11360-9VA0A$102.25 MSRP: $144.42You Save: $42.17 (30%)Ships in 1-2 Business DaysNissan Versa Engine Mounting Insulator ,Right

Part Number: 11210-5RA1A$167.86 MSRP: $248.53You Save: $80.67 (33%)Ships in 1-3 Business DaysNissan Versa DAMPER Assembly

Part Number: 11246-1HC2A$60.32 MSRP: $85.20You Save: $24.88 (30%)Ships in 1-3 Business DaysNissan Versa Engine Mounting Insulator, Front

Part Number: 11210-EL00A$132.97 MSRP: $192.58You Save: $59.61 (31%)Ships in 1-3 Business DaysNissan Versa Engine Mounting Bracket, Driver Side

Part Number: 11253-EL21A$51.21 MSRP: $70.60You Save: $19.39 (28%)Ships in 1-3 Business DaysNissan Versa Engine Mounting Support, Driver Side

Part Number: 11254-1KA0A$154.31 MSRP: $217.95You Save: $63.64 (30%)Ships in 1-3 Business DaysNissan Versa Engine Mounting Bracket, Left

Part Number: 11253-EL00A$53.78 MSRP: $74.13You Save: $20.35 (28%)

Nissan Versa Engine Mounting Bracket, Rear

Part Number: 11332-EL00A$21.63 MSRP: $29.82You Save: $8.19 (28%)

| Page 1 of 3 |Next >

1-20 of 47 Results

Nissan Versa Engine Mount

If you need any OEM Nissan Versa Engine Mount, feel free to choose them out of our huge selection of genuine Nissan Versa Engine Mount. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Versa Engine Mount Parts Questions & Experts Answers

- Q: What should be done if engine mounts are broken or deteriorated on Nissan Versa?A:Engine mounts seldom require attention, but broken or deteriorated mounts should be replaced immediately to prevent added strain on driveline components that may cause damage or wear. During the check, the engine must be raised slightly to remove the weight from the mounts. Begin by raising the vehicle and securely supporting it on jackstands, then remove the splash shields. Position a jack under the engine Oil Pan with a large wood block between the jack head and the oil pan, carefully raising the engine just enough to relieve the weight on the mounts, avoiding placement of the wood block under the oil pan drain plug. Inspect the mounts for any cracks, hardened rubber, or separation from the metal plates, noting that the rubber may split down the center. Check for relative movement between the mount plates and the engine or frame using a large screwdriver or prybar; if movement is detected, lower the engine and tighten the mount fasteners. Applying rubber preservative can help slow deterioration. For replacement, some models feature active engine mounts that require disconnecting the vacuum line before removal. Disconnect the cable from the negative terminal of the battery, raise the vehicle, and support it securely on jackstands while supporting the engine. To remove the front engine mount, support the engine with a jack and a block of wood, then take out the through-bolt and the mount-to-chassis bolts. For either of the two lower engine mounts, remove the through-bolts and the bolts retaining the mount to the subframe, followed by the engine block-to-mount bolts to remove the mount. Installation follows the reverse order of removal, using thread-locking compound on the mount bolts and nuts, ensuring they are tightened securely.

Related Nissan Versa Parts

Browse by Year

2024 Engine Mount 2023 Engine Mount 2022 Engine Mount 2021 Engine Mount 2020 Engine Mount 2019 Engine Mount 2018 Engine Mount 2017 Engine Mount 2016 Engine Mount 2015 Engine Mount 2014 Engine Mount 2013 Engine Mount 2012 Engine Mount 2011 Engine Mount 2010 Engine Mount 2009 Engine Mount 2008 Engine Mount 2007 Engine Mount