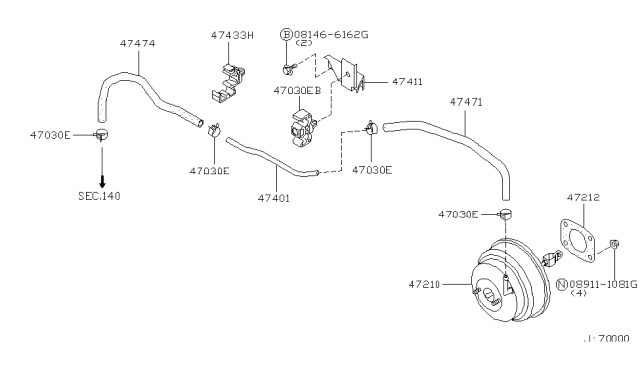

In addition to the specified intervals, the brakes should be inspected every time the wheels are removed or whenever a defect is suspected. Symptoms that could indicate a potential brake system defect include the vehicle pulling to one side when the brake pedal is depressed, squealing or dragging noises when the brakes are applied, excessive brake pedal travel, a pulsating pedal, or brake fluid leaks, usually onto the inside of the tire or wheel. Begin by loosening the wheel lug nuts, then raise the vehicle and place it securely on jackstands before removing the wheels. Each caliper contains two pads (an outer and an inner) that are visible with the wheels removed. Check the pad thickness by looking at each end of the caliper and through the inspection window in the caliper body; if the lining material is less than the specified thickness, replace the pads, noting that the lining material is riveted or bonded to a metal backing plate, which is not included in this measurement. If it is difficult to determine the exact thickness of the remaining pad material, or if there are concerns about the condition of the pads, remove the caliper(s) and then the pads for further inspection. Once the pads are removed, clean them with brake cleaner and re-measure them with a ruler or a vernier caliper. Measure the disc thickness with a micrometer to ensure it has service life remaining; if any disc is thinner than the specified minimum thickness, replace it. Even if the disc has service life remaining, check its condition for scoring, gouging, and burned spots; if these conditions exist, remove the disc and have it resurfaced. Before installing the wheels, check all brake lines and hoses for damage, wear, deformation, cracks, corrosion, leakage, bends, and twists, particularly near the rubber hoses at the calipers, ensuring that all hoses and lines are clear of sharp edges, moving parts, and the exhaust system. If any issues are noted, repair, reroute, or replace the lines or fittings as necessary. To check the brake booster, sit in the driver's seat and perform a series of tests: with the brake fully depressed, start the engine; the pedal should move down slightly when the engine starts. With the engine running, depress the brake pedal several times; the travel distance should not change. Depress the brake, stop the engine, and hold the pedal in for about 30 seconds; the pedal should neither sink nor rise. Restart the engine, run it for about a minute, and turn it off, then firmly depress the brake several times; the pedal travel should decrease with each application. If the brakes do not operate as described, the brake booster has failed. For the parking brake, one method of checking it is to park the vehicle on a steep hill with the parking brake set and the transmission in Neutral; if the parking brake cannot prevent the vehicle from rolling, it needs adjustment. On 2004 and later models, inspect the parking brake shoes for wear; the lining material on the parking brake shoes can be seen by pulling the adjusting hole plug out of the rear brake disc and looking into it with a flashlight while rotating the disc. If the friction material is worn thinner than the limit, replace the parking brake shoes.

Posted by NissanPartsDeal Specialist