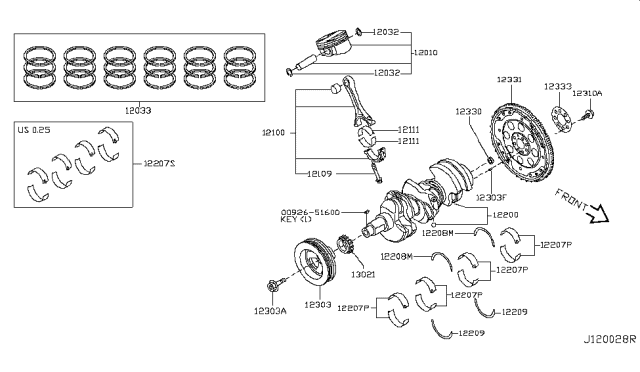

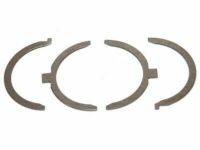

At least the crankshaft can be removed only after the removal of the engine from the car presuming that drive plate, crankshaft pulley, timing chain, oil pan, oil pump, oil filter and piston/connecting rod assemblies are also removed from the crankshaft. To do this, first remove the No. 1 bearing cap. Next, with the engine at TDC, zero a dial indicator on the crankshaft. Loosen the crankshaft and using the indicator, set it to zero while applying force on the crankshaft towards the back then apply force toward the front, the right difference should be between 0.003 to 0.010 inch. In the endplay, surpassing this range, should warrant an investigation on the levels of wear of the thrust washer/bearing assembly. If none are spotted, new main bearings can cure the problem. If a dial indicator is not available feeler gauges are used to measure clearance as explained below. Slowly, the main bearing cap bolts should be loosened to the point that they can be removed manually Then, the main bearing beam and related parts should be removed while paying respect to orientation. Slowly raise the crankshaft out of the engine block, preferably with the help of another person, because of its heavy weight. Bolt in the main bearing caps and beam just enough to engage threads and make sure they are in the correct direction. During installation, some basic checking should involve the engine block, the crankshaft and their surrounding environment in regard to cleanliness. Turn the block on the transverse plane with the base end up, unbolt the assembly of the main bearing caps, and clean the bearing seats. New inserts are to be fixed in the upper main bearing and the oil holes are to be aligned with each other and the lower inserts should be fitted in the caps. Scrape the crankshaft and place it to the right position; ensure that the thrust washers are placed correctly. Examine the status of the main bearing oil clearance with the help of Plastigage, and make sure that it corresponds to the standard parameters. If clearance is wrong, check for cleanliness and, if needed, different bearing sizes. When the Plastigage residue has been cleaned, apply a thin layer of grease or assembly lube on the bearing surfaces as well as the thrust faces and then lay the crankshaft back in position. Position the main bearing caps and support beam in the correct position and then fasten the bolts to the correct torque. Check again end-play of a crankshaft and turn the crankshaft to be sure that it does not bind on any of the bearings. Last of all, replace the new rear main oil seal and retainers.

Posted by NissanPartsDeal Specialist