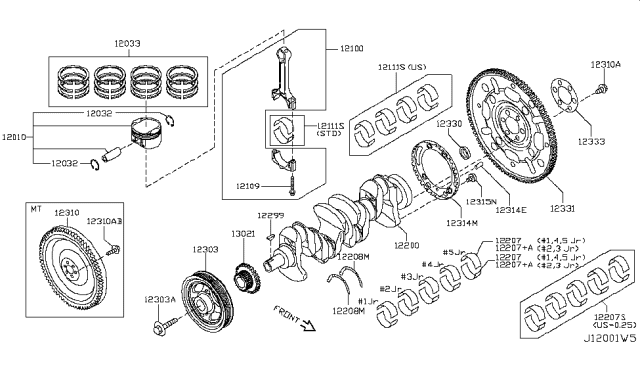

To ensure reliability, purchase Nissan part # 12201-ED81A Crankshaft Assembly. It can be referred to as Crankshaft. The first option would be to use OEM parts. Designed by Nissan manufacturer and are produced with stringent factory specifications, undergoing the quality control procedures. This part fits 2009-2014 Cube, 2007-2012 Versa.

NissanPartsDeal.com is a leading supplier of genuine Nissan parts and accessories, such as 12201ED81A Crankshaft Assembly. Welcome to our vast selection of competitively priced genuine Nissan parts available online. We provide each OEM part with a manufacturer's warranty and a straightforward return policy. Place your order now and receive your parts quickly, shipped directly to your doorstep.