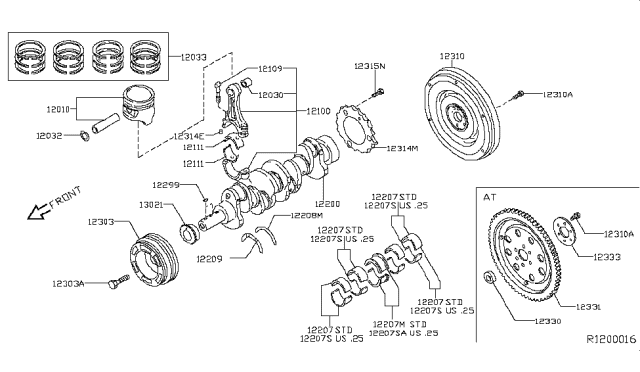

However, prior to inspection, piston/connecting rod assemblies have to be cleaned, the original piston rings then have to be removed from the pistons, and new rings always have to be installed on the pistons. Take out the rings off these pistons using a piston ring installation tool without scratching the rings or the pistons. Clean the top of the piston to remove any carbon build up by using a hand held brass wire brush or fine emery cloth dipped in solvent, do not use wire brush fitted on a motor because it can erode the soft material of the piston. Carbon deposits should be cleaned from the ring grooves using a piston ring groove-cleaning tool but a piece of the old ring can be as effective provided that he or she does not take along any metal or scratch the groove. Once the deposits have been removed, flush the piston/rod assemblies with solvent and air-dry them making sure that the oil return holes are NOT restricted. If the pistons and cylinder walls are basically sound and have not been machined oversize to increase engine displacement, new pistons probably aren't needed; however, new piston rings always should be installed during a rebuild. Every single piston, cylinder surface, should be examined for cracks, scoring, scuffing, holes and burned areas, because all these signs can tell about overheating and abnormal combustion, and in such a case, the cooling and lubrication systems must be checked. Universally distributed pitting indicates the coolant intrusion into the combustion chamber or crankcase, which has to be fixed to avoid similar occurrence in the future. Use a feeler to check the side clearance and record the reading in different places, in the grooves of the pistons; make sure that the accurate ring is fitted correctly in each groove; if the gaps are too wide, new pistons will need to be purchased. Checker procedure should be to measure the bores and accompanying pistons; if the clearance is more than designated-the block must be rebored and pistons and rings replaced. Piston to rod clearance can be determined by trying to twist the piston and the rod in different directions; if there are visible misalignments then this MUST be culled, and may require resizing of the bore (or others means) and new pins by an automotive machine shop. In case pistons have to be separated from the connecting rods, the latter also must be taken to the machine shop to check for bend and twist further, the connecting rods should be visually checked for cracks and damage, the rod caps and old bearings are to be removed temporarily, the surfaces must be cleaned and then checked whether there were any nicks or scratches before the bearings are replaced and the caps are tighten. In any case if the engine is being rebuilt because of connecting rod knock, new or rebuilts rods must be fitted.

Posted by NissanPartsDeal Specialist