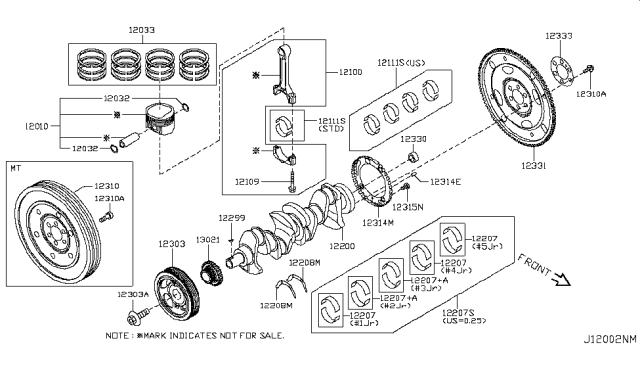

Before fitting new piston rings, the ring end gaps must be checked by laying out the piston/connecting rod assemblies and the new piston ring sets to match the ring sets with the same piston and cylinder during the end gap measurement and subsequent engine reassembly. Insert the top ring into the first cylinder and push it down the bore using the top of the piston to ensure the ring remains square with the cylinder walls, pushing it down until the piston skirt is level with the block mating surface before withdrawing the piston. Measure the end gap using feeler gauges and compare the measurements with the specifications; if the gap is too small, it must be enlarged to prevent the ring ends from contacting each other during engine operation, which could cause serious damage. Ideally, new piston rings providing the correct end gap should be fitted, but if necessary, the end gap can be increased by carefully filing the ring ends with a fine file, taking care as piston rings are sharp and easily broken. If the gaps are too large, check that the correct rings for the engine and cylinder bore size are being used. Repeat the checking procedure for each ring in the first cylinder and then for the rings in the remaining cylinders, ensuring that rings, pistons, and cylinders are matched up. Once the ring end gaps have been checked and corrected if necessary, the rings can be fitted to the pistons, following any instructions supplied with the new piston ring sets, as different manufacturers may specify different procedures. The oil control ring, composed of three separate components, is installed first by slipping the expander into the groove, then installing the upper side rail into the groove between the expander and the ring land, followed by the lower side rail in the same manner. Next, install the second ring, ensuring it is the correct way up and fitting it into the middle groove on the piston without expanding it more than necessary. Finally, install the top ring in the same way, ensuring it is the correct way up, and where the ring is symmetrical, fit it with its identification marking facing upwards. With all the rings in position on the piston, space the ring end gaps correctly and repeat the procedure for the remaining pistons and rings.

Posted by NissanPartsDeal Specialist