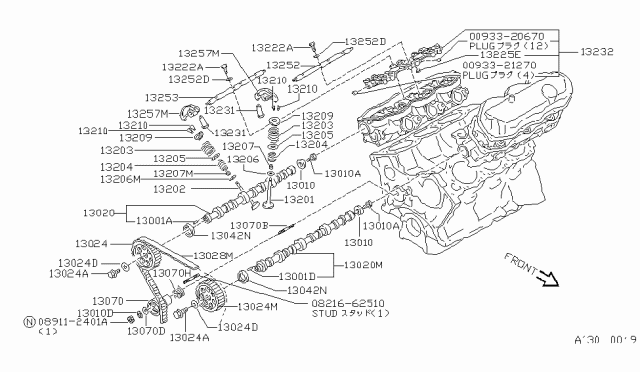

Visually check the camshaft bearing surfaces for pitting, scoring, or any abnormal wear; if damaged, the head must be replaced. Measure the outside diameter of each camshaft bearing journal and record the measurements, then measure the inside diameter of each corresponding camshaft bearing tunnel with a vernier caliper and record those measurements. Subtract each cam journal outside diameter from its respective cam bearing tunnel inside diameter to compute the oil clearance for each bearing and compare the results to the specified journal to bearing clearance; if any measurements fail to meet standard wear limits, either the camshaft or the head, or both, must be replaced. Check camshaft runout by placing the camshaft between two V-blocks and setting up a dial indicator on the center journal, zeroing the dial indicator, and turning the camshaft slowly while noting the readings; if the measured runout exceeds the specified limit, replace the camshaft. Measure the camshaft cam lobe height with a micrometer, compare it to the specified height, and compute wear on the cam nose; if the wear exceeds the specified limit, replace the camshaft, repeating this for each cam lobe. Inspect the contact and sliding surfaces of each Lash Adjuster for wear or scratches, noting that if the Lash Adjuster pad is worn, the corresponding camshaft lobe may also be worn. Measure the outside diameter of each Lash Adjuster with a micrometer and compare it to the specified diameter; if worn beyond the limit, replace it, as Lash Adjusters can be purchased individually. Check each Lash Adjuster bore diameter in the Lash Adjuster guide assembly against the specified tolerance; if worn beyond the limit, the Lash Adjuster guide assembly must be replaced. Subtract the outside diameter of each Lash Adjuster from the inside diameter of its Lash Adjuster bore and compare the difference to the specified clearance; if both are within acceptable limits, this measurement should also fall within tolerance, but new Lash Adjusters or a Lash Adjuster guide assembly may affect this. Inspect the rocker arms and rocker shafts for abnormal wear and scratches, measure the outside diameter of the rocker arm shaft at each journal with a micrometer, and compare the measurements to the specified outside diameter. Measure the inside diameter of each rocker arm with either an inside micrometer or a dial caliper and compare to the specified inside diameter. Finally, subtract the outside diameter of each rocker arm shaft journal from its corresponding rocker arm inside diameter to compute the clearance and compare these measurements to the specified clearance; if any fall outside the limits, replace either the rockers or the rocker shaft, or both.

Posted by NissanPartsDeal Specialist