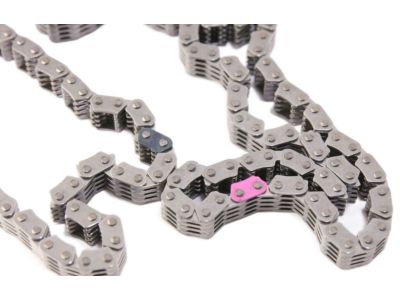

The timing system is complex, and severe engine damage will occur if mistakes are made. Only highly experienced individuals should attempt this procedure, and if there is any uncertainty, consulting an expert is advised. Double-check all work to ensure correctness before starting the engine. Begin by having a qualified air conditioning shop recover the refrigerant from the air conditioning system, then relieve the fuel system pressure and disconnect the negative battery terminal. Block the rear wheels, set the parking brake, raise the front of the vehicle, and support it securely on jackstands. Drain the cooling system, power steering fluid, and engine oil, then remove the power steering fluid reservoir, top and bottom engine covers, right inner fender splash shield, and front air inlet duct. Remove the intake manifold collector, valve covers, and dipstick, and position the number one piston at TDC on the compression stroke. Remove the drivebelt, upper radiator hose, lower radiator hose, coolant reservoir, cooling fan assembly, starter, power steering pump, air conditioning compressor, alternator and its bracket, and crankshaft pulley, ensuring the crankshaft does not rotate during removal. Disconnect wiring from the oil pressure switch and valve timing control wiring harness, label and disconnect any other interfering wiring and hoses, then remove the bolts from the IVT covers in reverse of the tightening sequence. Remove the drivebelt tensioner, air conditioning idler pulley and its bracket, and the bolts of the front timing chain cover in reverse of the tightening sequence, prying the cover off using the slots at the top. Remove the O-ring below each intake camshaft sprocket, confirm the number one piston is still at TDC, relieve tension on the primary timing chain, and lock the primary tensioner in place. Remove the primary timing chain tensioner, tensioner pivot arm/chain guide, and upper timing chain guides, then depress and lock the secondary timing chain tensioners. Remove the camshaft sprocket bolts, disengage the primary timing chain from the sprockets, and mark the camshaft sprockets before removing them along with the secondary timing chains. Remove the crankshaft sprocket and lower timing chain guide, then inspect the camshaft, water pump, and crankshaft sprockets for wear, as well as the chains and chain guides. Before starting the engine, carefully rotate the crankshaft by hand through at least two full revolutions, checking for resistance. Install the crankshaft sprocket and lower timing chain guide with the mark facing up, verify the correct timing chains, and reinstall secondary tensioners if removed. Position the camshafts correctly, install secondary timing chains and sprocket assemblies, and ensure timing marks are aligned. Install the primary timing chain, upper timing chain guides, primary tensioner arm/chain guide, and timing chain tensioner assembly, confirming the number one piston is still at TDC and timing marks are aligned before removing the stopper pin from the primary timing chain tensioner. Tighten the camshaft sprocket bolts, remove old sealant from the timing chain cover, install new O-rings, apply RTV sealant to the timing chain cover sealing surfaces, and install the cover and bolts in their original locations, tightening them in the recommended sequence. Install new O-rings in the IVT orifices and apply RTV sealant to the variable valve timing actuator covers, placing them in position and tightening the bolts. The remainder of the installation follows the reverse order of removal, adhering to sealant manufacturer's recommendations for assembly and curing times. Fill the crankcase with oil, install a new filter, refill the cooling system, reconnect the battery, and perform necessary re-learn procedures. Timing chain noise may be apparent after this procedure, which is normal and should subside as air bleeds out of the primary timing chain tensioner; if the noise persists, run the engine at 3,000 rpm until it diminishes.

Posted by NissanPartsDeal Specialist