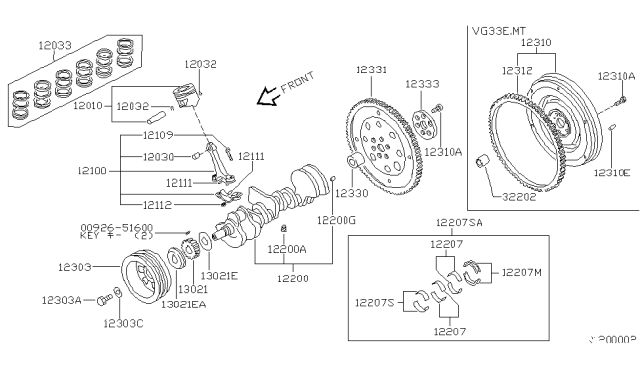

To ensure reliability, purchase Nissan part # 12200-0W001 CRANKSHAFT Assembly. It is sometimes referred to as Nissan Crankshaft. OEM parts are the #1 choice in terms of quality. Crafted by Nissan, they follow rigorous factory specs and go through the demanding quality control processes during manufacturing. This part fits 1999-2004 Nissan Frontier, 1998-2003 Nissan Pathfinder, 1999-2003 Nissan Quest, 2000-2004 Nissan Xterra.

NissanPartsDeal.com is a leading supplier of genuine Nissan parts and accessories such as Nissan 122000W001 CRANKSHAFT Assembly. Welcome to our vast selection of competitively-priced genuine Nissan parts available online. Each OEM Nissan part we provide is backed by a manufacturer's warranty and is subject to a stress-free return policy. Place your order now and receive your parts quickly, shipped directly to your doorstep.