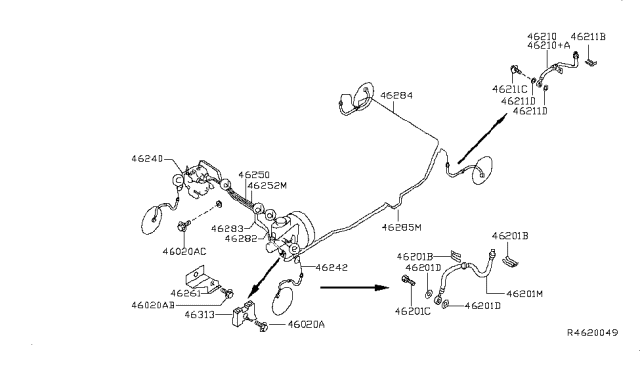

About every six months, with the vehicle raised and supported securely on jackstands, inspect the rubber hoses connecting the steel brake lines with the front and rear brake assemblies for cracks, chafing, leaks, blisters, and other damage, as these are crucial parts of the brake system. A light and mirror will aid in a thorough check, and any hose showing signs of wear should be replaced. To replace a flexible brake hose, loosen the wheel lug nuts, raise the vehicle, and remove the wheel. Unscrew the brake line fitting from the hose at the bracket using a flare-nut wrench to avoid rounding off corners, then remove the U-clip from the female fitting at the bracket and pass the hose through. At the caliper end, remove the banjo bolt and separate the hose, ensuring to replace the two copper sealing washers during installation. Detach the hose from the strut bracket by removing the U-clip. For installation, pass the caliper fitting end through the strut bracket, connect it to the caliper with the banjo bolt and new copper washers, ensuring the hose isn't twisted. Route the hose into the frame bracket, connect the brake line fitting by hand, install the U-clip, and tighten securely. Afterward, bleed the brakes, install the wheel and lug nuts, lower the vehicle, and tighten the lug nuts to the specified torque. When replacing metal brake lines, use the correct steel parts and avoid copper tubing. Prefabricated brake lines with flared tube ends and installed fittings are available, but they must be bent to the proper shapes using a tubing bender. Ensure the new line is securely supported in the brackets with adequate clearance from moving or hot components. After installation, check the master cylinder fluid level, add fluid as necessary, bleed the brake system, and test the brakes carefully before driving.

Posted by NissanPartsDeal Specialist