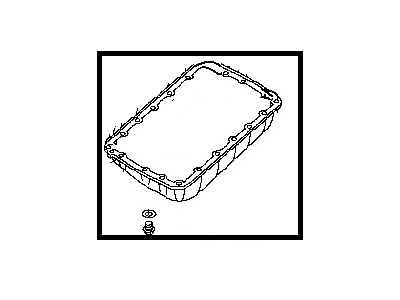

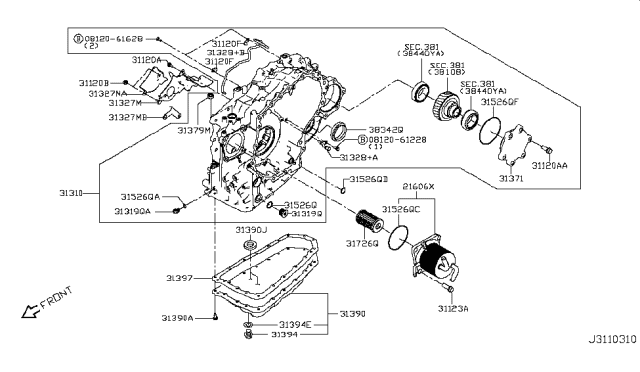

The undertaking entails the stripping off of two pans; the lower steel oil pan and the upper aluminum oil pan with the notion that if only the lower pan is being stripped off, a number of steps may not be taken since the pan is easily accessible. On 2.0L engines, the upper oil pan is best reached by separating the engine and transaxle; the oil pump is located with the upper pan, and therefore, cannot be removed individually. Start off by first removing the negative terminal of the battery, then the lugs that holding the right front wheel, placing and topping the car on jackstands safely and finally removing the right front wheel. Sump the engine oil, remove the front portion of the exhaust pipe and the drive belt. On smaller 2.5L engines, the right side of the car, take off the driveaxle bearing bracket and air conditioning compressor; however, leave the lines connected. For the vehicle of 2.0 L power unit, the timing chain cover, timing chain, and oil pump drive chain and sprocket have to be dismantled. Next, remove the flywheel/driveplate. This is made up of a two-part system, consisting of a steel pan fixed to an aluminum piece that is bolted onto the engine; to dismantle the oil pan, undo the oil pan bolts in a backward sequence of how they were tightened and then you can separate the steel part using a thin putty knife more so do not pry the part using a screwdriver. While on 2.5L engines, there are fasteners that holds the oil pump screen and on 2.0L engines, the oil pump an the screen are fixed there permanently. First loosen the bolts that fixed the aluminum section to the engine block, and trim the sealant around the aluminum section with putty knife and then pry it down at the transaxle end. For installation, use a scraper to remove old gasket material and sealant on the flanks of the metallic surfaces, clean the areas that the bolts are to screw into, and make sure they are clean. Make sure the steel pan flange has not distorted and needs to be repaired if it has. Spread a 3/16-inch wide strip of RTV sealant around the section of aluminum, and replace the O-rings if there are Some, place the section of aluminum on the engine block, then put the bolts in and tighten them in a star pattern to the recommended torque. Cookie all the round RO sealant in the steel pan perimeter and set the pan in the RV within 15 minutes by successively applying torque to the bolts. Re-install the removed parts by substituting the old oil filter with the new one, wait for at least half an hour before adding oil to let the RTV set, reconnect the battery and perform any re-learn operations.

Posted by NissanPartsDeal Specialist