×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 240SX Differential

Front Differential- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Differentials found

Nissan 240SX Differential

If you need any OEM Nissan 240SX Differential, feel free to choose them out of our huge selection of genuine Nissan 240SX Differential. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Differential Parts Questions & Experts Answers

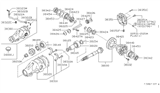

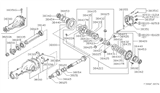

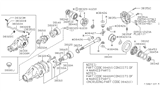

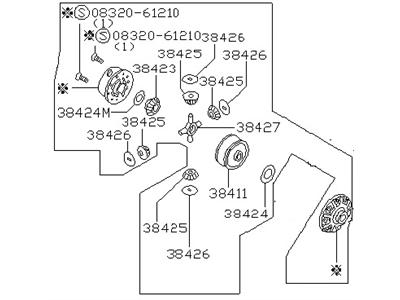

- Q: What are the steps and considerations involved in overhauling a differential assembly on Nissan 240sx?A:Overhaul entails having special tools and mechanics, in addition to automotive aptitudes, in reference to the service procedure. Start dis-assembly by fitting the differential assembly into a holding fixture and marking one side of the side bearing cap, to allow for refitting in its required orientation so that caps are re-fitted in their respective positions. Lose and take off the side bearing caps, to lift the differential easily from the housing while keeping the side bearing housings' outer races marked, and to take out the companion flange with the help of the special tool by loosening the drive pinion nut. Remove the rear bearing inner race and the drive pinion along with the bearing spacer, and adjusting washer, followed by an oil seal, the pilot bearing with the spacer, front bearing inner race, side oil seals, pinion bearing outer races, pinion rear bearing inner race, and pinion height adjusting washer. For the examination, examine ring gear and drive pinion for signs of scoring cracking or chipping and then replace them if needed. Ensure that the differential case assembly mating surfaces are in good condition and examine bearings for signs of wear or damage and replace if so. For assembly, place side gears, pinion gears, thrust washers, and a thrust block to the differential case, fit the pinion mate shaft and check the gear; thrust washer clearance. Insert the lock pin, apply gear oil to it, mount the differential case on the ring gear, tighten all bolts, while starting with the opposite corners and applying Loctite in between. Push on the side bearing inner races and the front and rear bearings, and turn to the pinion height adjusting washer, and position this washer and the rear bearing inner race. Place the drive pinion assembly to the differential carrier, fit the front oil seal and then torque the pinion nut. Check and set the amount of preload on pinion bearing and innstall the differential case assembly with side bearing outer races on the gear carrier. Fit side bearing adjusting washers, thread in the inside bearing spacer, fit and align the bearing cap at the same time, grease cavity of the oil seal. Check backlash and measure pinion and ring gear face width comparing it with the specifications in the design, and shim thickness in case it is required, to get the total preload. Check backlash and reverse from ring gear to maximum backlash and view the tooth contact pattern before fitting rear cover and gasket.