×

- Live Chat

- 1-888-726-6993

My Garage

My Account

Cart

Genuine Nissan 240SX Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Drive Belts found

Nissan 240SX Alternator Belt

Part Number: 11720-26E02$36.58 MSRP: $50.38You Save: $13.80 (28%)Ships in 1-3 Business DaysNissan 240SX Alternator Belt

Part Number: 11720-26E12$36.58 MSRP: $50.38You Save: $13.80 (28%)Ships in 1-3 Business DaysNissan 240SX Compressor Belt

Part Number: 11950-71E00$22.84 MSRP: $31.47Limited AvailabilityYou Save: $8.63 (28%)Nissan 240SX Power Steering Oil Pump Belt

Part Number: 11950-40F00$16.82 MSRP: $23.17You Save: $6.35 (28%)

Nissan 240SX Drive Belt

If you need any OEM Nissan 240SX Drive Belt, feel free to choose them out of our huge selection of genuine Nissan 240SX Drive Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Drive Belt Parts Questions & Experts Answers

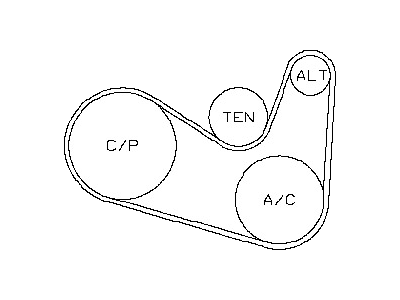

- Q: How should drive belt deflections be inspected and adjusted for optimal performance on Nissan 240sx?A: Inspect drive belt deflections when the engine is cold, and if hot, check after waiting 30 minutes or more. Check the belts driving the fan, power steering pump, air conditioning compressor, and alternator for cracks, fraying, wear, and tension every 12 months or 15,000 miles after 60,000 miles or 48 months of vehicle use, replacing as necessary. Used belt deflection at the midpoint of the longest span between pulleys should be less than 1/2 inch (13mm) with 22 lbs. (10kg) of pressure, while new belt deflection should be less than 1/3 inch (8mm) under the same pressure. To adjust the tension on a component without an idler pulley adjustment or adjusting bolt setup, loosen the pivot and mounting bolts of the component, then use a wooden lever to pry the component toward or away from the engine until the proper tension is achieved, and securely tighten the mounting bolts. An overly tight belt can wear out the pulley bearings, and if a new belt is installed, recheck the tension after driving about 1,000 miles. Belt tension adjustments for the factory-installed air conditioning compressor and some other components may be made at the idler pulley, which is the smallest of the three pulleys; loosen the lock nut on the idler pulley to free the adjustment bolt, then adjust and tighten the lock nut afterward. For the power steering oil pump and some alternator applications, adjustments are made at the pump or component adjusting bolt; loosen the lock bolt and securing bolt, adjust until the belt deflection is correct, and then tighten everything securely. When replacing a drive belt, loosen the pivot and mounting bolts of the component, use a wooden lever to relieve tension, slip the belt off, and ensure the new belt matches the old one in length and width before adjusting the tension. When replacing multiple belts, it is advisable to note or mark the routing of each belt for easier installation. For air conditioning compressor and power steering pump belt replacements, loosen the lock bolt for the adjusting bolt and then the adjusting bolt, pry the pulley or pump inward to relieve tension, and take care not to damage any components.