×

- Live Chat

- 1-888-726-6993

My Garage

My Account

Cart

Genuine Nissan Titan Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Exhaust Valves found

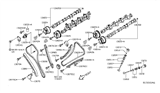

Nissan Titan Valve-Exhaust

Part Number: 13202-EZ30A$22.55 MSRP: $31.07You Save: $8.52 (28%)Ships in 1-2 Business DaysNissan Titan Valve-Exhaust

Part Number: 13202-9FP0A$7.87 MSRP: $10.83You Save: $2.96 (28%)Ships in 1-2 Business DaysNissan Titan Valve-Exhaust

Part Number: 13202-EZ31A$22.55 MSRP: $31.07You Save: $8.52 (28%)Ships in 1-3 Business Days

Nissan Titan Exhaust Valve

If you need any OEM Nissan Titan Exhaust Valve, feel free to choose them out of our huge selection of genuine Nissan Titan Exhaust Valve. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

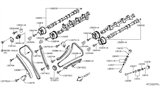

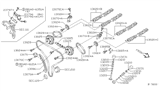

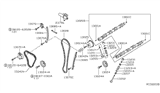

Nissan Titan Exhaust Valve Parts Questions & Experts Answers

- Q: How to check and adjust valve clearance after replace camshaft(s) or valve-related parts on Nissan Titan?A: The manufacturer recommends checking and, if necessary, adjusting the valve clearance after replacing the camshaft(s) or other valve-related parts, or if the valve train is making excessive noise. Begin by disconnecting the cable from the negative terminal of the battery, then remove the spark plugs. Position the number 1 piston at TDC on the compression stroke and align the timing marks before removing the valve covers. Check that the intake and exhaust camshaft lobes for cylinder number 1 are pointed outward. Measure the clearance of the indicated valves with a feeler gauge; at TDC for number one cylinder, the intake valve clearance for cylinders no. 1, no. 2, no. 4, and no. 5 can be measured, along with the exhaust clearance for cylinders no. 1, no. 7, and no. 8. Record each measurement and compare with the desired valve clearance specifications, noting any that are out of specification for later determination of required replacement lifters. Turn the crankshaft 270 degrees clockwise to place cylinder number 3 at TDC and measure the clearances of the indicated valves, then turn the crankshaft 90 degrees clockwise to TDC for cylinder number 6 and measure the clearances for the indicated valves. If a lifter is out of specification for clearance, it must be replaced with a new lifter of a different thickness to correct the clearance. Mark the lifters to be replaced and record their origin, using a micrometer to measure the thickness of the lifter head precisely. To calculate the correct thickness for a replacement lifter that will achieve the specified valve clearance, use the formula: N = R + (M1 - M2), where N is the thickness of the new lifter, R is the thickness of the old lifter, M1 is the measured valve clearance, and M2 is the standard valve clearance. New lifters are available in 25 standard thicknesses, ranging from 0.3102 inch to 0.3291 inch, marked on the underside to indicate their size. Mark the new lifters for their destination, lubricate them with engine assembly lube, and install them. After replacing the lifters, reinstall the camshafts and timing chains, then re-check the valve clearances.

Related Nissan Titan Parts

Browse by Year

2022 Exhaust Valve 2021 Exhaust Valve 2020 Exhaust Valve 2019 Exhaust Valve 2018 Exhaust Valve 2017 Exhaust Valve 2016 Exhaust Valve 2015 Exhaust Valve 2014 Exhaust Valve 2013 Exhaust Valve 2012 Exhaust Valve 2011 Exhaust Valve 2010 Exhaust Valve 2009 Exhaust Valve 2008 Exhaust Valve 2007 Exhaust Valve 2006 Exhaust Valve 2005 Exhaust Valve 2004 Exhaust Valve